Imagine you are trying to cool down a piping hot cup of coffee. You could blow on it, but what if you could instantly transfer that heat into something else without ever mixing the liquids? That is the magic of industrial cooling, and at the heart of it all is a compact powerhouse called the brazed plate heat exchanger.

Now, I know what you are thinking. Engineering equipment sounds a bit dry, doesn’t it? Well, hold on a second!

When you see a brazed plate heat exchanger animation, it is like watching a high-tech dance of thermodynamics. It is sleek, it is efficient, and it is honestly pretty cool to witness. Whether you are an engineer in Sydney or a project manager in Perth, understanding these units through 3D visuals is a total game-changer.

Shall we dive into why these little boxes are the unsung heroes of the industrial world?

Why Is Everyone Obsessed With 3D Animation for Industrial Engineering Projects?

Let’s be real. Blueprints are great, but they can be a bit of a headache to read. If you are trying to explain a complex thermal process to a client or a new technician, a flat drawing just does not cut it. This is where 3D modeling steps in to save the day.

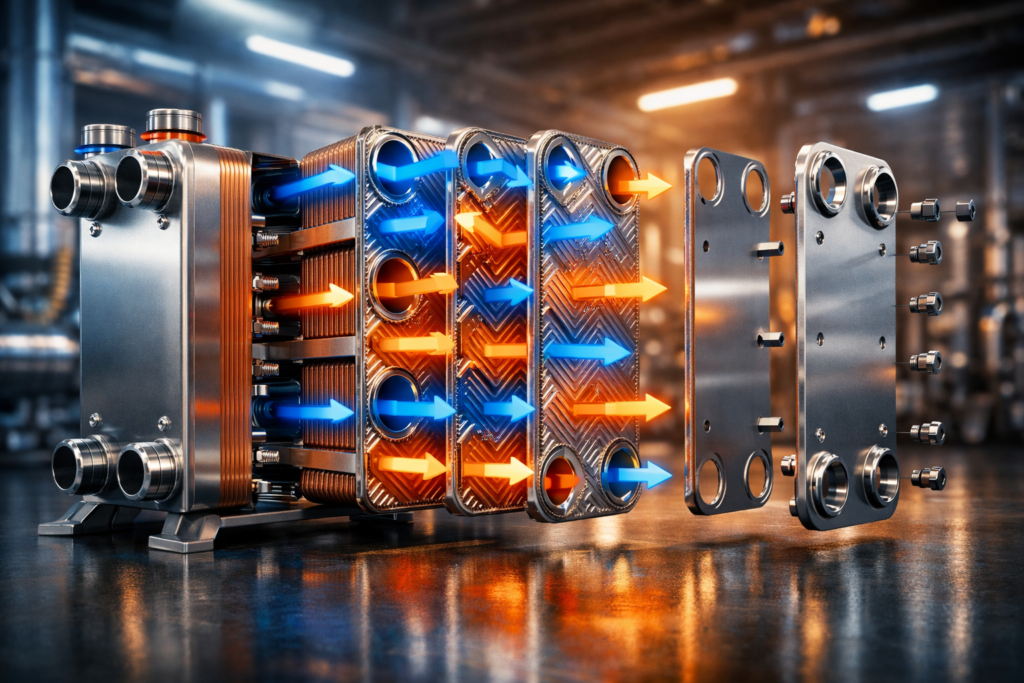

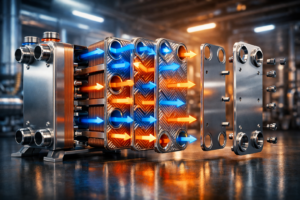

When we create a brazed plate heat exchanger animation, we are not just making a pretty movie. We are building a tool that shows exactly how fluid moves through those thin, corrugated stainless steel plates.

-

It builds trust: Clients can see the internal quality for themselves.

-

It simplifies training: No more guessing which pipe goes where.

-

It sells the vision: It is much easier to sign off on a project when you can see the heart of the machine beating in 3D.

If you are working with big gear, you might find our 3D animation for heavy machinery in Australia super helpful for seeing the bigger picture!

The Magic Inside: How Does a Brazed Plate Heat Exchanger Work in Real Time?

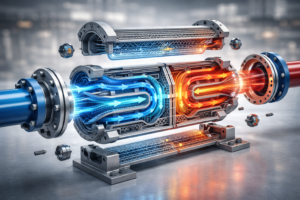

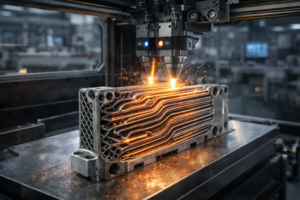

Okay, let’s get technical but keep it simple. A brazed plate heat exchanger consists of a series of thin, corrugated plates. These plates are brazed, which is basically high-temp vacuum welded, together using copper or nickel.

Inside, there are two separate paths. One path is for your hot fluid and one is for your cold fluid. Because the plates are so thin and have a large surface area, the heat literally jumps from the hot side to the cold side. Wow, right? Efficiency at its finest!

Using a brazed plate heat exchanger animation, you can actually see the counter-current flow. This is where the fluids travel in opposite directions to maximize the temperature difference. It is the secret sauce that makes these units so much smaller than the old-school shell and tube monsters.

Taking It Apart Virtually: Why You Need 3D Assembly and Disassembly Animation

Have you ever tried to explain how to maintain a unit that is completely sealed? It is tough! While brazed units are mostly maintenance-free because they do not have gaskets, understanding their connection points is vital for installation.

This is where a ghosted or exploded view in an animation becomes your best friend. You can see the stack of plates, the end covers, and the four ports coming together in perfect harmony.

If you want to see how we handle complex teardowns visually, check out our complete guide to 3D assembly and disassembly animation. It is a lifesaver for technical manuals!

Safety First! Improving Australian Workplace Safety with 3D Simulations

In the industrial world, a failure in a heat exchanger is not just a minor oops. It can be a major safety hazard. High pressures and extreme temperatures are no joke.

By using a brazed plate heat exchanger animation, companies can simulate what-if scenarios. What happens if the pressure spikes? Where are the stress points?

This visual data is crucial for machine safety in Australian workplaces, ensuring that operators know exactly how to handle the equipment before they even touch a wrench.

Let’s Talk Numbers: The Boring But Important Stuff!

I promised some stats to back this up, so here is why the world is moving toward brazed technology and 3D visualization:

-

Efficiency Boost: According to research on thermal systems, brazed plate heat exchangers can be up to 25% to 40% more efficient in heat transfer than traditional shell-and-tube designs of the same size.

-

Market Growth: The global heat exchanger market is projected to reach over $22 billion by 2030, with brazed versions leading the charge in the HVAC and refrigeration sectors.

-

Visual Learning Impact: Studies in educational psychology suggest that people retain 65% more information when it is presented visually through 3D animation compared to text-based manuals.

Why Small 3D Details Make a Massive Difference in Engineering

When you are pitching a multi-million dollar engineering project, you need every advantage you can get. A high-quality brazed plate heat exchanger animation shows that you care about precision. It shows that you are not just selling hardware; you are selling a solution that has been meticulously planned.

Can you imagine trying to explain the chevron pattern on a plate without a visual? It is like trying to describe a sunset to someone who has never seen one. The animation does the heavy lifting for you!

So, What Is the Big Takeaway for Your Next Project?

We have covered a lot of ground! From the way heat jumps across stainless steel plates to the reason why 3D visuals are the secret weapon for modern engineering firms.

A brazed plate heat exchanger animation is not just a marketing gimmick. It is a bridge between a complex idea and a successful installation. It saves time, prevents errors, and makes your project look incredibly professional. Whether you are designing a new HVAC system or upgrading an industrial plant, seeing the flow in 3D changes everything. Are you ready to bring your engineering designs to life? I would love to help you visualize your next big breakthrough.

Would you like me to walk you through how we can create a custom animation for your specific machinery?

FAQs: Brazed Plate Heat Exchanger Animation for Industrial Systems

How does a brazed plate heat exchanger work?

It works by passing two fluids of different temperatures through alternating layers of corrugated metal plates. The heat is transferred through the plate walls from the hot fluid to the cold fluid without the two ever mixing. Because the plates are brazed together in a vacuum furnace, the unit is incredibly strong and leak-proof, even under high pressure.

What is the 2- 3 rule heat exchanger?

The 2/3 rule is a common rule of thumb in maintenance and design regarding the pressure limits between two sides of a heat exchanger. Generally, it suggests that if the lower-pressure side can withstand at least 2/3 of the design pressure of the higher-pressure side, the risk of a catastrophic rupture leading to an over-pressurization of the shell is significantly reduced. It is all about preventing big bangs in the factory!

What is the difference between a brazed plate heat exchanger and a plate heat exchanger?

The main difference is the seal. A standard plate heat exchanger (PHE) uses rubber gaskets to keep the plates together and prevent leaks; these can be taken apart and cleaned. A brazed plate heat exchanger is permanently welded together. This makes the brazed version much more compact and able to handle higher temperatures and pressures, though it cannot be opened for manual cleaning.

What are the 4 types of heat exchange?

The four primary methods are conduction, convection, radiation, and phase change. Conduction involves heat moving through a solid material, while convection involves heat moving through fluids. Radiation is heat moving via electromagnetic waves, and phase change involves states like evaporation or condensation. In our heat exchanger, we are mostly dealing with a beautiful mix of conduction and convection!

Are brazed heat exchangers easy to maintain?

Since you cannot open them up, you cannot just scrub them with a brush. Instead, we use a process called Clean-in-Place or CIP. You flush a cleaning solution through the system to dissolve any scale or buildup. It is fast, but you have to stay on top of it to prevent fouling, which is engineering-speak for getting gunked up!