Planning an efficient factory layout may not seem thrilling at first glance, but anyone in Australian manufacturing knows it has its moments. With tight deadlines, complex machinery, strict safety rules, and pressure to improve workflow performance, things can get complicated quickly. And let’s admit it… relying on old 2D drawings feels a bit outdated when the entire future of your production line is on the line. No surprise that more engineering teams now lean on Engineering animation for factory layout, which can greatly enhance understanding of complex manufacturing processes through immersive 3D walkthroughs, to watch their layout come alive before construction even starts.

By using 3D animation, detailed 3D models, and advanced visualization tools, engineers get an immersive, real-world preview of a complete industrial plant. They can experiment with workflow ideas, shift equipment around effortlessly, validate automation, and present complex engineering concepts in a way that makes sense to everyone in the room.

This article explores how animation elevates factory layout planning in Australia, how production teams benefit from it, and why it is fast becoming a must-have tool in industries that rely heavily on precision engineering.

Why Animation Matters in Factory Layout Planning?

Modern factories, including a real-world factory, contain a mix of robotics, automation systems, material handling equipment, safety procedures, and complex processes. When everything depends on accurate setup, relying only on static drawings can lead to design flaws, wasted money, and workflow disruptions.

Animation offers a visual, interactive, and easy-to-understand representation of what the factory will look like when fully operational, enhancing the design and construction process. Instead of studying diagrams, teams can watch industrial processes unfold through a 3D industrial animation that represents the actual workflow in the engineering project.

Australian manufacturers are increasingly adopting this approach. Leveraging 3D digital visualization tools can reduce layout-related errors by improving clarity. Deloitte adds that immersive animation can speed up stakeholder approvals by providing a virtual tour of the project. Up to 50 percent of the 3D plant design can be achieved by incorporating specific equipment tailored to the workflow because decision makers understand layouts instantly.

These numbers reflect why more engineering teams are upgrading to animation-driven planning that leverages advanced 3D technology for better management of wastewater treatment plants.

Using Animation and 3D Visualisation to Explore Factory Designs

A major advantage of animation is the ability to walk through the industrial plant virtually and explore every technical detail. Instead of viewing a floor plan, teams can see machinery, production lines, conveyor paths, utilities, safety zones, and worker movement inside a realistic environment, highlighting key features of the workflow.

3D Industrial Animation for Complete Layout Exploration

A fully animated industrial plant allows you to:

-

zoom into machinery

-

rotate complex systems

-

Animation allows teams to examine product flow in a more interactive way.

-

Study automation pathways

-

analyse bottlenecks

-

Check equipment spacing

-

test emergency access routes

-

validate operator pathways

Animation transforms the factory from a concept into a visual experience. It acts as an explainer for both engineering backgrounds and non-technical stakeholders.

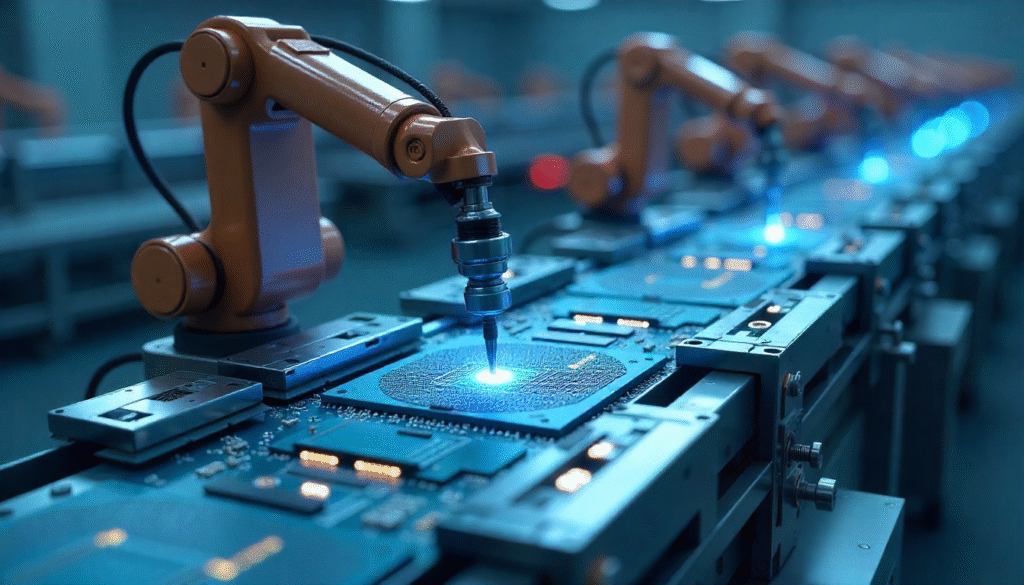

Animation Services That Show Machinery in Motion

Machinery placement is one of the most challenging parts of factory design, particularly when creating a 3D engineering animation. Animation services allow you to see how machines behave in a real manufacturing environment, particularly for specific equipment. This includes:

-

Robotic arm movements

-

Animation allows for a detailed view of conveyor flow, optimizing efficiency in manufacturing.

-

Timing sequences

-

Assembly interactions can be effectively communicated through animation to showcase the efficiency of the workflow.

-

Loading and unloading patterns

-

Cycle speeds

-

Realistic 3D visualization of product features

Technical animation helps identify design flaws long before equipment arrives on-site.

Walkthrough Videos That Improve Stakeholder Communication

Nothing communicates a complex idea better than a visual walkthrough or product animation. A 3D walkthrough lets supervisors, investors, operators, and engineers tour the future facility before construction. It shows production lines, technical systems, automation flows, and workflow interactions in a way that eliminates confusion through interactive 3D visuals.

Animation becomes a universal language that connects all stakeholder groups, especially when enhanced by immersive 3D technology.

Simulating Automation and Workflow Behaviour Through 3D Animation

Simulation is one of the strongest reasons engineering teams in Australia use animation during layout planning. Instead of waiting for physical installations, they can test the automation and industrial processes digitally.

Simulating Complex Industrial Systems

A complete manufacturing animation can serve as a powerful tool for visualizing complex processes in a smart 3D format. 3D animation for industrial equipment allows engineering teams to simulate various scenarios effectively, including those involving specific equipment.

-

Robot Reach

-

Conveyor Speeds

-

Product Flow

-

Animation Allows for the Visualization of Access Zones, Ensuring Safety and Efficiency in Operations

-

Timing Sequences

-

Assembly Steps

-

Material Handling

-

Technical Systems

-

Process Flow Through the Production Line

Simulation helps predict real-world performance with technical accuracy. Engineers can refine workflows, adjust timing, test alternative configurations, and validate automation choices with confidence.

Technical Animation for Detailed Equipment Validation

A technical animation replicates the internal mechanisms of machinery. This is especially important for:

-

Multi-Stage Machines

-

Robotic Cells Are Often Highlighted in Product Animation to Demonstrate Their Functionality

-

Complex Conveyor Systems

-

Packaging Lines

-

Sorting Systems Can Be Optimized Using Sophisticated 3D Animations to Illustrate the Workflow and Efficiency of Plant Operators and Maintenance Personnel

-

Automated Tools

Technical animation shows how everything works together, allowing the team to check alignment, maintenance access, worker safety, and operational behaviour.

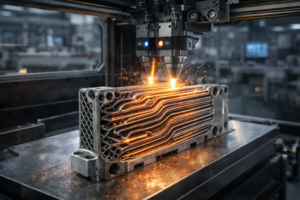

Visualising an Entire Production Line Before Construction

Manufacturing animation can reveal issues that engineers may overlook in 2D drawings. These include:

-

Layout congestion

-

Blocked pathways

-

Incorrect material flow

-

Equipment overlap

-

Training plant operators and maintenance personnel can improve awkward operator access on specific equipment.

-

Unrealistic cycle times

These insights help refine the entire factory layout with much greater precision and efficiency through advanced 3D modeling.

Tip:

When planning your animation project, always provide your animation company with complete CAD files, technical specifications, and engineering notes for accurate video production. This ensures technical accuracy and prevents repeated revisions. The more precise the CAD data, the more realistic and reliable the smart 3D industrial animation becomes, enhancing the overall design process.

Using Industrial Animation for Safety, Training, and Operator Education

Safety is a major priority across Australian factories, especially for plant operators and maintenance personnel. 3D animation for safety provides a powerful tool for clearly demonstrating safety protocols, which are essential for handling specific equipment.

Visualising Safety Procedures in a Realistic 3D Environment

Using animation, teams can simulate:

-

Lockout tagout procedures

-

Hazardous zones

-

Emergency shutdown steps

-

Fire evacuation routes can be effectively illustrated through advanced 3D animations to ensure safety compliance.

-

Worker movements

-

Collision risks with automation

-

Operator access to machinery is a critical consideration in the interactive 3D design of the factory.

This level of visualization helps prevent incidents and improves worker confidence.

Training Operators and Maintenance Personnel Efficiently

Maintenance teams often struggle to understand complex equipment layouts through manuals alone. Animation solves this by showing:

-

Internal mechanisms

-

Maintenance steps

-

Service access points

-

Part replacements

-

Lubrication points can be highlighted in manufacturing animations to ensure precision and efficiency in maintenance.

-

Cleaning sequences can be demonstrated through immersive 3D animations to enhance training and operational understanding.

This reduces training time and improves understanding across teams.

Showcasing Technical Systems Across an Entire Industrial Plant

Animation can display large-scale systems, utilizing 3D representations of manufacturing processes to enhance understanding.

-

Power distribution

-

HVAC

-

Wastewater systems

-

Compressed air networks

-

Material handling routes

-

Automation connections

This is ideal for planning and for onboarding new team members.

Partnering With an Animation Company for Factory Layout Planning

Many companies prefer to outsource to an animation company that specialises in industrial 3D animation. These teams understand engineering principles, technical accuracy, and how to translate complex systems into clear visuals, focusing on key features of the design.

Why Animation Services Deliver Better Project Outcomes

Professional animators help with:

-

Converting CAD files to 3D models

-

Ensuring realistic textures and lighting is crucial for showcasing industrial processes convincingly in a wastewater treatment plant

-

Preserving mechanical accuracy is crucial when creating advanced 3D animations for industrial applications

-

Creating a simulation of real machinery motion

-

Structuring a complete animation video is essential for effective communication of the assembly line processes

-

Showcasing industrial processes convincingly is vital for training plant operators and maintenance personnel

-

Translating complex ideas into visual content

Their expertise makes the final layout more reliable and efficient.

Explainer Animations for Presentations and Online Platforms

Explainer animations simplify communication by presenting:

-

Product features

-

Workflow interactions

-

Technical systems

-

Assembly sequences

-

Safety protocols

These animations are excellent for internal presentations, investor discussions, and online platforms used for training or marketing.

Refining Plant Layouts Before Physical Construction Starts

Animation enables teams to refine layouts before spending money on construction, maximizing the benefits of industrial design. It helps answer questions like:

-

Does the equipment placement make sense?

-

Is the workflow efficient when viewed through an immersive 3D animation perspective?

-

Are safety zones adequate?

-

Does the automation behave correctly?

-

Are there any hidden design flaws?

This saves time, prevents costly changes, and creates more efficient industrial plants.

Where Engineering Animation is Most Useful in Australia

Australian industries that benefit from animated factory layout planning include:

-

Food and beverage manufacturing

-

Metal fabrication is essential for creating specific equipment used in various manufacturing processes

-

Packaging and distribution

-

Mining and mineral processing

-

Engineering fabrication

-

Pharmaceuticals

-

Automotive assembly

-

Heavy industrial plants

-

Logistics and warehousing

These industries rely on complex industrial systems and benefit greatly from visualizing the full workflow before construction.

Ready To See Your Factory Before It’s Even Born?

Engineering animation for factory layout gives Australian manufacturers something they never had before: the ability to see their entire industrial plant, explore every workflow, test automation, validate machinery, and spot design flaws long before construction begins. What used to take weeks of back-and-forth drawings can now be understood in a single animated walkthrough, showcasing the benefits of industrial design.

With 3D visualization, technical animation, and immersive industrial modelling, engineering teams gain clearer communication, stronger safety planning, better production line design, and more confident decision-making. Stakeholders understand instantly, operators learn faster, and complex industrial systems become easy to showcase.

In short, animation lets you plan smarter, build safer, operate smoother, and deliver results with precision.

If you want to turn complex industrial processes into clear, engaging visuals, check out the full range of engineering animation services.

Frequently Asked Questions

Can I use CAD models to build factory layouts?

Yes. CAD models can be imported directly into a 3D animation environment to create accurate factory layouts. This ensures the plant design and equipment placement remain technically correct, especially when viewed in a 3D plant format with key features highlighted.

Can I use animation to test how a machine will perform?

You can. Technical animation simulates machine movement, cycle timing, clearance zones, and interactions with surrounding equipment. It is one of the most effective ways to test performance before installation.

How does engineering animation help in visualizing complex systems?

It provides a realistic 3D representation of workflows, automation, utilities, and internal mechanisms, helping train plant operators and maintenance staff. Even complex systems become easy to understand when shown through animated visualization.

Can animation help with safety training?

Yes. Animation can demonstrate emergency procedures, hazardous zones, equipment start-up processes, and safe operating steps. Workers understand faster because they see actions visually.

Why should engineering teams use 3D animations for plant design?

3D animations help prevent design flaws, improve communication, validate automation, and visualise the entire workflow clearly. Teams make better decisions and avoid costly mistakes during construction.