The UK mining industry is going through a major digital transformation, and one of the most exciting parts of this shift is how digital twin technologies are teaming up with 3D animation. More companies are now turning to 3D animation services in the UK to bring their equipment and processes to life in a clear, visual way. A digital twin is basically a digital replica of a physical asset, such as machinery, a process plant, or even an entire mining workflow. When you combine it with 3D animation, simulation tools, sensors, and real-time data, mining companies can monitor equipment, simulate ore movement, improve efficiency, and boost productivity with much more confidence.

This change is not only about introducing new tech. It is also about adopting smarter digital twin solutions that help facilities work better, cut down on downtime, and move toward more sustainable operations. Plus, it makes complicated mining tasks so much easier to understand because teams can now look at a digital model that actually behaves like the real thing.

Why Digital Twins in the Mining Sector Matter for Every Site?

Digital twins in the mining sector help companies overcome everyday challenges. Whether you look at a gold or an iron ore mine, the idea is the same. You use a sophisticated digital twin to simulate mining operation workflows, track machinery health, and monitor real-time data from sensors.

Here is why it matters:

-

Better decision making through clear analytics and real-time data.

-

Stronger safety in modern mining operations because miners can simulate risks before entering.

-

Less downtime since teams detect failures early using advanced control systems.

-

Improved productivity due to better visibility into the mineral processing stages of the mining process.

Deloitte’s mining digital transformation reports emphasize trends like maturity assessments and operational enhancements but lack the specified 15% productivity figure. Surveys highlight varying digital maturity across firms, with “pockets of excellence” rather than uniform gains.

Global digital transformation spending reached about 1.8 trillion USD around 2022, per IDC data, not Statista or mining-specific projections for 2025. Mining digital markets are far smaller, e.g., projected at 37.53 billion USD in 2025 growing to 77.91 billion by 2032, or 5 billion USD in digital spending for 2025.

Mining tech adoption grows via automation and analytics, with smart mining at 16.87 billion USD in 2025. Broader DX spending may exceed prior forecasts, but not at the claimed scale or attribution.

How Using a Digital Twin Creates a Smarter Mining Operation?

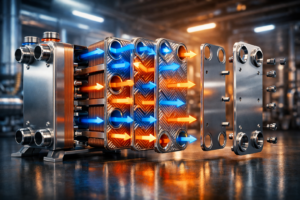

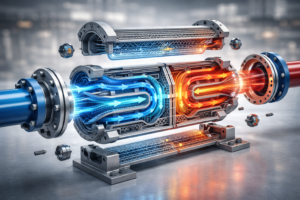

A digital twin works by collecting information from sensors placed on machinery, conveyors, drills, and trucks throughout the entire mining value chain. The Internet of Things connects these physical assets to a digital model, enhancing the potential of digital technologies in mining. With the support of 3D Product Visualization, this model becomes even more useful because teams can clearly see how equipment and processes look and behave in a realistic digital format. It uses real-time data, simulation, and machine learning to show how the operation is performing and where improvements can be made.

What a typical digital twin includes

-

3D animation and visuals of machinery and underground layouts

-

Sensor data from physical equipment is crucial for creating a digital twin.

-

Real-time analytics dashboards

-

Simulation tools to test new layouts or mining and mineral workflows

-

Predictive maintenance alerts

Teams can also leverage machine learning to predict failures and avoid costly downtime. Using digital twins in the mining environment is becoming one of the safest and most transparent ways to understand how a mine truly behaves, particularly with the uptake of digital technology.

Top Benefits of Digital Twin Technologies for the Industry

Improve Efficiency and Reduce Downtime

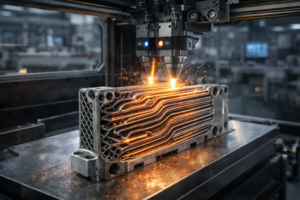

Using digital twin simulation technology helps companies predict when a machine will fail. Predictive maintenance, enabled by the use of a digital twin, is one of the biggest benefits because it stops breakdowns before they happen.

Support Sustainability Goals

Mining companies face pressure to reduce energy use and environmental impact, driving the adoption of Industry 4.0 solutions in the future of mining. A digital model helps simulate energy consumption, ore flow, and fuel usage so teams can find more sustainable options.

Increase Productivity at Every Site

Digital twins help identify delays in the mining process, from drilling to hauling, in many mining operations. Even small optimizations increase overall productivity.

Better Training for Miners Through 3D Animation

Instead of learning through traditional manuals, miners can watch 3D animation that shows exactly how machinery works. This makes training easier and safer.

How Animation and Simulation Improve Digital Transformation in the Mining Sector?

Industrial 3D Animation adds visual clarity to the sophisticated digital twin. Complex machinery, mineral processing stages, and underground layouts become much easier for teams to understand when these visuals are paired with digital twins. The combination helps everyone see what is happening in the operation without getting lost in technical details.

Animation supports:

-

Simulation of heavy machinery movements

-

Training scenarios for new miners

-

Hazard identification is crucial for ensuring safety at the mine site.

-

Visualizing the impact the mining activities may create

-

Understanding ore flow and equipment loads is essential for optimizing underground mines using digital twin technology.

When companies implement a digital twin combined with animation, the mining industry becomes more transparent and easier to manage.

Comparison Table: Type of Digital Twin Models in the Mining Sector

| Type of Digital Twin | What the digital twin represents in mining and resources. | How It Helps Mining with digital twins in mining. |

|---|---|---|

| Asset Digital Twin | A single physical asset like a drill or truck can be enhanced with a digital representation. | Predictive maintenance, reduced downtime |

| Process Digital Twin | The entire mining process from drilling to hauling is enhanced by the development of digital twins. | Simulate ore flow, improve efficiency |

| System Digital Twin technology providers are essential for successful implementation. | A group of connected assets | Optimize mining operation workflows |

| Environmental Digital Twin | The site environment and surroundings are crucial for integrating digital twin technologies within the mining projects. | Support sustainability and impact analysis through the use of a digital twin. |

These types help companies choose the right level of detail when planning the implementation of digital tools.

How Digital Twins and Process Optimisation Impact the Industry?

Digital twins and process optimisation work together to create smoother mining and mineral operations by embracing digital technology. Simulation tools allow teams to test different layouts, estimate ore quality outputs, and simulate production changes before they are applied in real life.

This reduces risk and ensures that the implemented digital improvements are well informed.

Tips for Using Digital Twins in the Industry

Here are simple tips for companies starting their digital journey:

-

Begin with one physical asset and scale gradually towards developing digital twins.

-

Use 3D animation to make training more engaging

-

Connect all machinery through sensors for better data in process control systems.

-

Use simulation to plan new mine layouts in alignment with sustainable mining goals.

-

Focus on sustainability improvements early in the project

-

Train miners to understand the digital model and data insights

A small start often delivers quick wins and builds confidence among mining organisations.

How Companies Have Implemented Digital Twin Technologies to Improve Efficiency?

Companies that have implemented digital twin tools often report reduced operational delays in their mining projects. Using digital twin platforms helps mining organisations track machinery status, improve ore recovery processes, and uncover small inefficiencies that were previously invisible by leveraging processing technology.

Machine learning algorithms can predict failures, while analytics tools reveal patterns that the human eye might miss. This digital transformation supports both long-term planning and day-to-day decisions inside the mine.

Conclusion: The Future of Digital Twins in the Mining Sector

Digital twins in the mining industry are transforming how the UK manages mines and physical assets using real-time data and robust digital infrastructure, especially in energy and water management. With 3D animation, simulation, sensors, and real-time data, teams gain clearer insights, miners train safely, and companies reduce downtime while improving sustainable mining practices.

As adoption of digital tools grows, the mining sector will continue to move toward a fully connected environment where every ore movement, machinery action, and mining process can be seen inside a digital replica. The future is smarter, safer, and far more efficient for every UK mine willing to leverage these technologies.

Turn your CAD files into something that actually wows people. Grab a free quote and see what’s possible.

FAQs: How 3D Engineering Models Transform Operations

Is a digital twin a 3D model?

A digital twin can include a 3D model, but it goes further by connecting real-time data from sensors, analytics, and machine behavior. It is a living digital replica rather than a static 3D model, crucial for modern mining operations.

How does a digital twin work in process mining?

It works by collecting data from machinery and workflows, then using simulation and information management to show how the mining process performs. This helps teams test scenarios and improve efficiency across the entire mining value chain by embracing digital twin technology.

What is digital twin technology in mining?

Digital twin technology in mining connects physical assets and machinery to a digital model using sensors, the Internet of Things, and analytics. It improves decision-making, predictive maintenance, and productivity through digital twin solutions.

What is 3D digital twin mapping?

3D digital twin mapping creates a visual and data-driven representation of a mine or asset, facilitating better decision-making for mining operators. It combines scanning, sensors, and 3D animation to show an accurate digital view of the real-world environment.