Australia’s industrial landscape is full of technical products and machinery that demand absolute clarity during build processes, particularly in mounting applications. Mining equipment, industrial machinery, fabricated components, and engineered systems all require precise, step-by-step assembly instructions that technicians must follow reliably. When manuals fail to illustrate complex assembly sequences clearly, mistakes occur and downtime increases. And frustrated technicians lose confidence, impacting their ability to use the engine effectively with new techniques.

This is why more companies across Australia now rely on 3D assembly and disassembly animations to present a complete, intuitive assembly process. These 3D animated assembly videos break down every component, show every step logically, and provide a crystal-clear assembly sequence that anyone can follow. Technicians no longer depend solely on traditional manuals, as they now have access to end-to-end solutions. Instead, they gain an immersive visualization that makes technical understanding easier and significantly reduces assembly errors, particularly in the piston assembly.

Using 3D animation allows companies to illustrate intricate assembly modules, show internal components like pistons, and walk viewers through step-by-step assembly instructions. A 3d assembly video can highlight what to remove first, show the correct alignment for every part, and demonstrate complex assembly actions in a way that text simply cannot.

This approach makes even the most complex assembly more intuitive, visual, and user-friendly, especially when using 3D video for mounting instructions.

Why 3D Assembly and Disassembly Animation Makes Training Effortless in Australia?

3D assembly and disassembly animations help technicians see what needs to be done, instead of guessing. This matters particularly in industries where equipment is large, expensive, or dangerous to assemble incorrectly. With visual storytelling and animation, technicians gain a clear, confident overview of the assembly process.

Traditional manuals often confuse workers. They attempt to explain complex processes with flat diagrams that lack depth, whereas 3D modeling provides a more comprehensive view of mounting procedures. They try to show the order of removal or installation, but unless the viewer already has technical expertise, misunderstandings about mounting and orientation occur. A 3D animated assembly video immediately showcases these issues.

Technicians can now follow interactive, step-by-step visuals, understand the purpose of every component, and visualize the entire assembly sequence before touching a tool, making the process easier. This ensures the process becomes predictable, efficient, and safer for everyone involved.

3D Assembly Modeling Makes Every Step Easy to Follow

Using 3D assembly animations provides clarity that text cannot achieve, making complex processes more understandable. When training technicians, nothing is more valuable than showing them exactly how each component interacts with the next. A 3D animated assembly video can illustrate how parts slide together, how bolts align, how modules rotate, and how internal systems must be oriented using cutting-edge technology.

This eliminates confusion. Instead of reading dozens of lines in a manual, technicians follow a smooth, visual, intuitive sequence. Step-by-step assembly instructions guide them through complex assembly without overwhelming them.

This is especially helpful for companies building technical products with internal components such as motors, conveyors, pumps, drive systems, robotic modules or industrial equipment used in manufacturing and mining.

Visualization enables workers to see the entire assembly process from a new perspective, dramatically enhancing technical understanding.

Visualization Improves Comprehension and Reduces Errors

Two major research bodies support the value of 3D visualization in technical fields, emphasizing its role in optimizing assembly processes.

The National Institute of Standards and Technology (NIST) highlights how 3D visualization reduces errors in manufacturing and assembly by helping teams understand complex components accurately.

CSIRO Australia also demonstrates how digital simulation and 3D visualization improve engineering comprehension, making it easier for technicians to integrate complex processes into their workflow.

These findings support what Australian companies experience in real-world settings, particularly with the implementation of cutting-edge technology. Using 3D assembly animations provides teams with clear visuals that reduce mistakes, increase efficiency, and help technicians follow assembly instructions correctly, especially during segment assembly.

3D visualization transforms complex processes into intuitive sequences, particularly for the assembly of intricate segments. When workers can see internal components and understand the purpose of each module through detailed animation, they assemble products faster and with fewer errors.

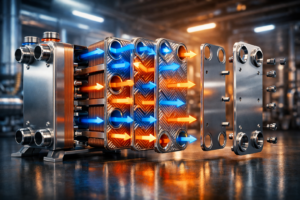

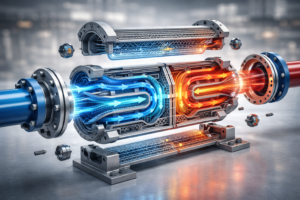

Cutaway Animations Reveal What Manuals Cannot Show

One of the most powerful features of technical 3D animation is the cutaway view. Cutaway animations reveal internal structures with perfect clarity. Workers can now visualize gears, wiring, hydraulic paths, bearings, seals, connectors, fasteners, and internal bolt locations.

Traditional manuals struggle to explain internal components, but 3D animated assembly videos clearly illustrate everything. A technician can rotate the view, zoom in on details, observe how internal components interact, and ensure each part is correctly installed during the assembly process, leveraging the engine using advanced techniques.

This is especially useful in mining, manufacturing, and engineering environments where equipment installation and automation must be implemented precisely.

Cutaway views are essential for teaching intricate assembly sequences, explaining disassembly steps, and demonstrating how internal mechanisms operate using 3D video.

Implement Technical Assembly Videos to Improve Accuracy and Efficiency

Technical assembly videos significantly reduce errors by removing guesswork from the disassembly and mounting process. When technicians follow a 3D animated assembly video, they know exactly what actions to perform. The sequence is intuitive, facilitated by detailed animations that guide technicians through each step, optimizing torque application during assembly. The visuals show correct assembly and provide an understandable overview of the mounting process, including proper orientation of each part. Labels guide each step. And the entire workflow becomes predictable and easy to follow, ensuring adequate orientation during assembly.

Using 3d assembly animations ensures consistent results across all teams. Whether the technician is experienced or new, the animation provides the same level of clarity. This helps companies reduce rework, prevent assembly delays, and avoid costly mistakes related to incorrect mounting or torque application.

3D animated assembly videos also increase technician confidence. When assembly instructions are clear and visual, workers feel more capable and less stressed during complex assembly tasks, especially during piston installations.

How are 3D Assembly and Disassembly Animations Created?

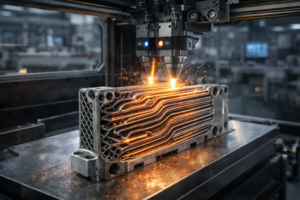

The creation of these animations follows a detailed, professional workflow.

Engineering teams first provide CAD files, manuals, diagrams, and technical documents that are essential for mounting components. These files serve as the foundation for the 3D animation process, providing a clear explanation of each step in the assembly optimization. The animator then builds a module-based structure so the assembly process can be presented step by step, showcasing the world on YouTube.

Each component is animated carefully. Movements are simulated in real time to reflect the actual mechanical behavior. Labels, arrows, callouts, and step numbers are added to guide the viewer through the assembly sequence, creating animations that enhance understanding of the piston installation.

The final technical assembly video is rendered in high resolution and can be used for technician training, customer support, internal engineering documentation, marketing videos, or YouTube demonstrations.

This approach ensures that every component is clearly illustrated and that the instructions feel intuitive and user-friendly, aiding correct part orientation.

Where are 3D Animated Assembly Videos used in Australia?

The use of assembly and disassembly animation has expanded across manufacturing, mining, industrial design, training, and engineering sectors, demonstrating its end-to-end capabilities. These animations are used for:

-

Training new technicians is made easier with the use of 3D animated content available worldwide on YouTube, which can be uploaded to enhance learning.

-

Improving assembly consistency can be achieved by implementing automation on the assembly line.

-

Teaching maintenance steps involves understanding the correct torque for each component.

-

Showing the entire assembly instruction sequence with detailed animation enhances understanding and retention of information, particularly regarding torque specifications.

-

Onboarding customers is made easier with interactive visuals that guide them through the assembly process, ensuring they understand the mounting sequence.

-

Supporting installation teams

-

Reducing errors during assembly

-

Simplifying complex processes

Many Australian mining suppliers rely on animation to demonstrate installation sequences for heavy machinery. More insights can be found here:

Manufacturers also use animation to train workers and market technical products, and there are lots of benefits of 3D animation for manufacturers looking to showcase complex equipment clearly and effectively.

This broad use confirms that 3D assembly and disassembly animation aligns with being a core communication tool for companies across Australia.

Why This Case Study Proves 3D Animation Is the Ideal Solution?

This Australian case study shows that 3D assembly and disassembly animation is far more than a modern training trend; it represents a cutting-edge technology shift. It is a practical, effective and highly detailed way to communicate complex assembly instructions.

Animation simplifies assembly for technicians, improves technical understanding, reduces assembly mistakes, enhances training quality, and transforms the user experience through interactive visuals. Whether the goal is to improve clarity, train technicians, or help customers understand technical products, 3D animated assembly videos are the ideal solution.

The Future of Technical Assembly Is Already Here

The biggest advantage of 3D assembly and disassembly animation is not just clarity. It is confidence that comes from detailed explanations and interactive training methods. When technicians understand every step visually, when customers can follow assembly instructions without confusion and when engineers can communicate complex processes effortlessly, everything becomes smoother, faster and more accurate.

This is why forward-thinking Australian companies are now embracing 3D assembly animations as a long-term solution. It improves user experience, eliminates costly mistakes, and transforms traditional manuals into powerful visual storytelling tools using cutting-edge technology.

If you want to see how industrial workflows, machinery, and engineering processes can be brought to life with cinematic technical accuracy, you can explore full industrial and engineering animation capabilities.

FAQs: 3D Assembly and Disassembly Animation

How does visualizing product assembly in 3D reduce errors?

Visualizing assembly in 3D helps technicians clearly see each component, movement and connection before they begin the task. This removes uncertainty that usually occurs with flat diagrams or text-heavy manuals, providing a more understandable approach to assembly. With clearer visuals, workers make fewer mistakes and follow the correct sequence confidently.

How do 3D assembly instructions simplify complex tasks?

3D assembly instructions break detailed procedures into small, intuitive steps that are easy to follow, focusing on the correct torque for each segment. Every movement, angle, and alignment is shown visually, reducing cognitive load. This explainer helps users understand complex tasks quickly, even with limited technical experience.

What is an exploded view animation and why is it useful?

An exploded-view animation separates all components so viewers can see exactly how each part fits together, enhancing understanding of mounting. This visual breakdown improves knowledge of internal structures and relationships. It is especially useful for teaching assembly, troubleshooting, and explaining technical products.

Can technical 3D animation be used for equipment assembly training?

Yes, technical 3D animation is widely used to train technicians across manufacturing, mining and engineering industries. It offers consistent, repeatable instruction that traditional manuals cannot match, optimizing the learning experience for technicians. This helps teams assemble equipment accurately and reduces the chance of errors during the segment assembly.

How is machine assembly animation used in industrial settings?

The machine assembly animation supports installation by clearly and visually showing each step. It also helps with maintenance training by illustrating disassembly and internal components safely. Many companies use it for engineering communication, customer onboarding and internal knowledge transfer.