Machine safety is one of the biggest training priorities across Australian workplaces, especially in construction, where the risks are high and the machinery is complex. If you work in mining, construction, manufacturing, or energy, you already know how quickly things can go wrong on a busy site. One small mistake can lead to serious injuries, and traditional training often falls short when it comes to explaining complicated safety procedures. That is exactly why so many organisations are now turning to 3D animation for machine safety to teach workers more clearly, improve safety outcomes, and support stronger WHS compliance.

More and more Australian companies are choosing animation, interactive visuals, and animated safety videos because they make training easier to understand and much more memorable. This shift reflects how modern teams prefer to learn, especially when dealing with site-specific hazards and complex machinery.

Below is a clear look at how Australian organisations use 3D animation, why it works so well, and how it supports Safe Work Australia guidelines and real-world hazard awareness.

Why Australian Companies Are Using Animation for Safety?

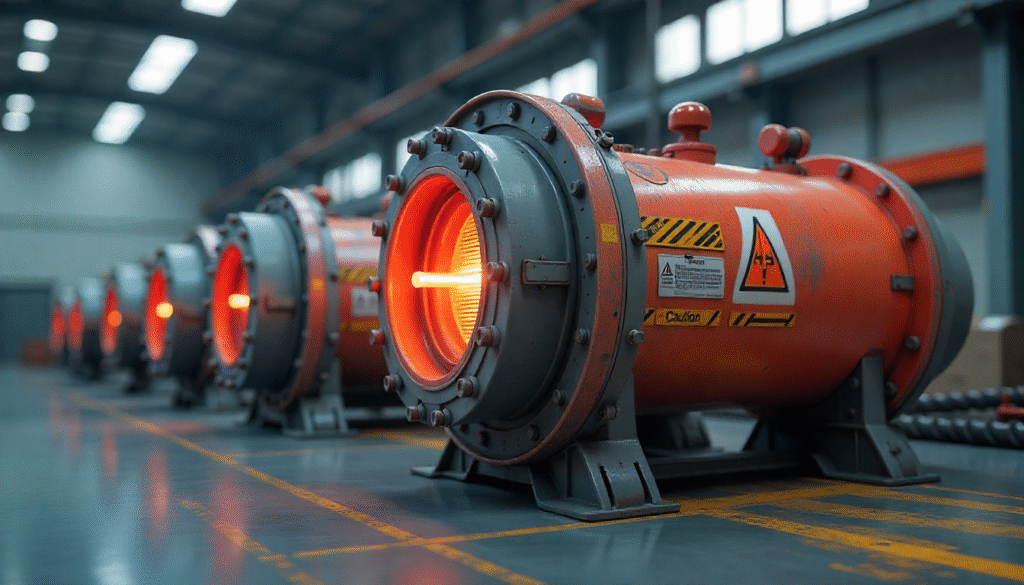

Many industries handle machinery that is too dangerous or too expensive to demonstrate in real time. Workers are often expected to understand safe work practices, correct safety procedures and traffic management rules without direct hands-on exposure. 3D animation for machine safety solves this problem by providing realistic 3D animations and accurate representations of equipment in action.

Animation allows teams to visualize complex machinery, mechanical movements, internal components, electrical hazards and pinch points that cannot be safely shown during a live demonstration. As a result, workers understand and follow safety procedures more effectively because they are not imagining hazards. They are seeing them clearly on screen.

Animations simplify complex topics such as:

-

High-risk tasks

-

Hazard identification

-

Lockout and tagout processes

-

Confined spaces

-

Emergency stops

-

Machine guarding

-

Pressure systems

-

Hydraulics and electrical systems

This makes training more engaging and memorable for workers at all skill levels.

How 3D Animation Supports Safe Work Australia Guidelines?

Safe Work Australia stresses the need for practical, engaging, and easy-to-follow WHS training. It encourages the use of tools that improve safety, support hazard awareness, and provide clear explanations of risk control measures. 3D animation for machine safety supports these principles in several ways:

-

Clear communication of safe work practices

Animations help workers visualize complex processes that would otherwise be difficult to explain with manuals or classroom instruction. -

Improved hazard identification

Workers can see exactly where hazards exist, including moving parts, risk zones, fall hazards and electrical dangers. -

Training consistency

Every worker receives the same message, which improves compliance and reduces miscommunication between shifts, particularly in high-pressure environments like construction sites. -

Better retention of safety information

Research on visual learning shows that people retain information much longer when they see it instead of simply reading or hearing it.

The following sources highlight that strong WHS programs benefit from accurate training content, clear communication, and realistic representation of hazards, all of which 3D animation provides for immersive learning experiences.

-

Safe Work Australia WHS performance and training guidelines.

-

National Institute for Occupational Safety and Health (NIOSH) research on visual learning and hazard awareness emphasizes the ability to visualize risks in the construction industry.

Why 3D Animation Works Better Than Traditional Training?

Traditional safety training relies heavily on printed manuals, induction PowerPoints, long verbal briefings and occasional on-site demonstrations. These formats often overwhelm workers with information.

Realistic 3D animations provide highly effective learning benefits

Using visual storytelling and animation allows teams to:

-

Visualize complex machinery before operating it

-

Understand step-by-step procedures

-

Watch detailed demos of machine operation

-

Learn workplace hazard awareness

-

Connect actions with consequences

-

Retain information for long-term safety

Animations are designed to show realistic risks in safe environments, including:

-

Crush zones

-

Machine pinch points

-

High-pressure system failures can be better understood through immersive learning techniques that transform complex information into accessible training.

-

Incorrect PPE choices

-

Traffic management errors

-

Electrical hazards during maintenance

Instead of simply telling workers what not to do, companies show real-world scenarios using engaging safety visuals.

The Power of Incident Animation

Another growing trend in Australia is the use of incident animation.

When a workplace accident happens, animators recreate the sequence using 3D animation. This helps organisations:

-

Learn from real-world accidents

-

Identify hazards more accurately

-

Improve internal investigations

-

Strengthen future training

-

Support communication with health and safety representatives

Incident animation is a highly effective way to explain complex safety failures without exposing workers to real danger.

Animation in the Mining Industry

Mining is one of Australia’s highest-risk sectors. Complex machinery, heavy equipment, underground environments, and site-specific rules make training difficult, but immersive learning can simplify these challenges.

Mining companies are increasingly turning to 3D animation because it allows them to:

-

Demonstrate traffic management routes

-

Train workers on emergency procedures

-

Show the safe operation of large equipment

-

Improve hazard awareness around haul trucks

-

Visualize complex construction or infrastructure layouts

-

Simplify high-risk activities such as blasting or pit entry

How 3D Animations Are Designed for Safety Training?

Australian companies follow a structured workflow to create site-specific, accurate safety animations. The process usually includes:

1. Collecting engineering data

Animators gather:

-

Operation manuals

-

Safe Work Australia documents

-

Photos and videos can be enhanced with 3D animation to create visually compelling training materials.

-

3D CAD files

-

Hazard assessments

-

WHS guidelines

-

Site-specific safety rules

2. Identifying key safety risks

Health and safety representatives work with animators to highlight:

-

Mechanical hazards

-

Manual handling risks

-

Electrical hazards

-

Traffic management patterns

-

Environmental risks

-

Incorrect PPE use

3. Creating accurate representations

Animators convert CAD files into 3D models and build realistic 3D animations that match the real equipment. They ensure every movement reflects real engineering behaviour so that workers can visualize complex mechanical motion safely and efficiently.

4. Adding safety protocols and procedures

This includes the ability to visualize high-pressure system failures and their consequences.

-

Step-by-step guidance

-

Safe work practices

-

Correct safety procedures are essential for transforming complex machinery operations into safe practices on construction sites.

-

WHS required signage

-

Hazard identification cues

5. Review and validation

Engineers, WHS managers and supervisors confirm accuracy before training begins.

This structured approach builds tailored solutions that are scalable, immersive and suitable for both induction and ongoing training.

The Role of LMS Systems in Delivering Animations

Many Australian organisations now deliver their training videos and visual learning materials through LMS platforms. This allows them to:

-

Assign training to specific teams

-

Track completion

-

Provide assessments

-

Deliver content remotely

-

Support multiple sites

-

Maintain training consistency

Animation is especially powerful in LMS environments because it works for both in-person training sessions and remote workforce training, enhancing long-term retention through immersive learning experiences.

2D Animation vs 3D Animation in Workplace Safety

Both 2D and 3D have roles in workplace safety, but they are used differently.

2D animation is useful for:

-

Simple diagrams

-

Instructional overlays

-

Process flow explanations

-

Basic hazard awareness

3D animation is essential for:

-

Heavy machinery is often used in construction sites, requiring comprehensive safety protocols to ensure worker safety.

-

Mechanical systems

-

High-risk environments

-

Complex construction

-

Confined space work

-

Real-world simulation

Most Australian safety teams now use a combination of both formats.

How Animation Builds a Safety-First Culture?

Safety training is not just about rules on a page. It is about building a consistent workplace culture where workers feel confident, informed, and supported. Animation helps build this safety-first culture because it:

-

Makes safety messages clearer

-

Helps workers understand risks instantly

-

Encourages discussion during training

-

Supports new workers and apprentices

-

Reinforces best practices in safety through the ability to visualize risks and scenarios on a construction site.

-

Improves compliance

When workers can articulate safety concerns and visualize complex machinery properly, organisations experience fewer incidents and stronger work health and safety performance.

This Is Why Smart Companies Are Paying Attention

Australian workplaces are turning to 3D animation for machine safety because it delivers clearer, stronger, and more consistent training than traditional methods. Animation allows workers to visualize complex machinery, understand high-risk tasks, and see correct safety procedures in a realistic and engaging way. This improves hazard identification, supports WHS compliance, and helps teams stay safe during daily operations.

Realistic 3D animations, incident animation, and visual training tools also make learning more memorable, which leads to fewer workplace accidents and stronger long-term retention. Whether used in mining, constructio,n or manufacturing, animation simplifies complex safety procedures and creates a safer workplace culture for everyone.

As organisations look for more effective training solutions, 3D animation continues to stand out as a practical and highly effective way to improve safety outcomes and support a safety-first culture across Australia.

Now is the perfect time to explore how to create an effective 3D explainer video that strengthens your safety training.

FAQs: 3D Animation for Machine Safety in Australian Workplaces

How to make a safety animation?

Safety animation is created by gathering engineering data, identifying hazards, modelling equipment in 3D and animating correct procedures. It is reviewed by WHS experts to ensure accurate representation of risks, particularly in the construction industry.

How can technology be used in animation?

Technology such as 3D modelling software, CAD data, motion simulation, rendering engines and real-time visualization tools helps animators create realistic training videos that mirror real workplace conditions.

How do safety training videos reduce accidents?

Safety training videos reduce accidents by improving hazard awareness, simplifying complex procedures and delivering consistent messages across all teams. Workers understand and follow procedures more easily when they visualize them clearly.

What technology are scientists in Australia experimenting with to improve mining?

Australian mining researchers are exploring visual simulation, automation systems, advanced robotics, and digital twins, all of which complement 3D animation for safer workplace training.

How long does it take to create a 3D Safety Animation Video?

Production time varies based on complexity. Simple animations may take two to three weeks, while complex machine simulations can take six to eight weeks due to modelling, scene development, and WHS approval.