Introduction

In today’s fast-paced engineering landscape, technology is transforming the way products are conceptualized, designed, and manufactured. 3D product visualization is a critical component in this transformation, especially when it comes to 3D prototyping for engineers. By turning abstract ideas into tangible, digital representations, engineers can streamline their design processes, reduce errors, and bring innovative products to market faster. This article explores how 3D product visualization and 3D rendering for engineering are revolutionizing the prototyping and design industries.

Understanding 3D Product Visualization in Engineering

The Basics of 3D Product Visualization

At its core, 3D product visualization is the process of creating realistic, interactive digital models of products before they are physically produced. Engineers use these visualizations to test designs, identify flaws, and make informed decisions. Unlike traditional 2D sketches or blueprints, 3D visualizations offer a more intuitive and precise understanding of the product’s functionality, look, and feel. To achieve this, engineers rely on various advanced 3D visualization and CAD (Computer-Aided Design) software like Autodesk Fusion 360, SolidWorks, Rhino, or Blender.

Key Benefits of 3D Rendering for Engineering

The integration of 3D rendering for engineering offers numerous advantages. It significantly reduces the time and costs associated with traditional prototyping methods. Engineers can easily modify designs, view them from different angles, and make real-time adjustments. This level of flexibility ensures that the final product is as close to perfection as possible before production begins.

Additionally, 3D visualizations enhance collaboration. Engineers, designers, and clients can all view and interact with the same model, ensuring clear communication and minimizing misunderstandings during the design process.

The Role of 3D Prototyping for Engineers

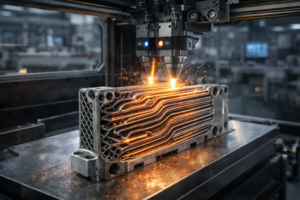

Transforming Traditional Prototyping Methods

Traditional prototyping often involved creating physical models from sketches or blueprints, which could be time-consuming and costly. With 3D prototyping for engineers, these models are created digitally and can be modified instantly. This not only speeds up the prototyping process but also allows for more accurate and cost-effective designs.

Enhancing Accuracy and Reducing Errors

One of the biggest advantages of 3D prototyping is the ability to detect design flaws early in the process. With a digital prototype, engineers can simulate how a product will function under real-world conditions. This early testing leads to fewer errors and less need for costly adjustments during the production phase, ensuring a smoother development cycle.

Advancements in 3D Rendering for Engineering

How 3D Rendering Improves Engineering Designs

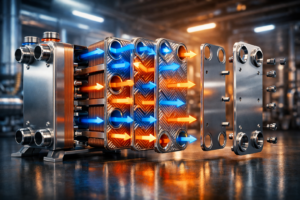

3D rendering for engineering is a game-changer in terms of visualizing complex structures. Engineers can generate highly detailed models of their designs, allowing them to explore every angle and feature. They can also simulate how materials and components will behave under different stressors or environmental conditions.

Integrating 3D Rendering with CAD Software

The compatibility of 3D rendering with Computer-Aided Design (CAD) software is another significant advancement. By integrating 3D rendering into CAD tools, engineers can easily generate realistic visualizations that align perfectly with their original designs. This seamless workflow eliminates the need for manual adjustments, saving valuable time and resources.

Digital Twin Technology: A Game-Changer for Engineers

What is Digital Twin Technology?

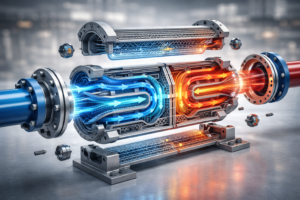

Digital twin technology is a revolutionary concept that creates a virtual replica of a physical object or system. For engineers, this means they can visualize and monitor a product throughout its lifecycle, from design to deployment. By combining digital twin technology with 3D product visualization, engineers can simulate product performance, predict issues, and optimize designs.

Benefits of Digital Twin Technology in Product Design

By utilizing digital twins, engineers can perform real-time simulations and monitor how their designs will behave in the real world. This level of accuracy not only helps reduce costs but also improves product quality. Engineers can make adjustments to the virtual model before it’s ever manufactured, ensuring that the final product meets the desired specifications.

3D Product Visualization in Industrial Design

The Role of Visualization in Industrial Design

In industrial design, 3D product visualization plays a critical role in moving from concept to creation. With the ability to see and interact with digital models, designers can make quick revisions, visualize materials, and experiment with different configurations—all without having to build physical prototypes. This flexibility enables quicker innovation and more efficient design processes.

The Intersection of 3D Visualization and Product Manufacturing

The integration of 3D visualization into industrial design ensures that the gap between design and manufacturing is minimized. Engineers can simulate production processes, identify potential manufacturing challenges, and even optimize material usage. This results in lower production costs, less material waste, and faster time-to-market for products.

Engineering Product Design: The Future of Prototyping

How 3D Product Visualization Drives Innovation

3D product visualization isn’t just about creating accurate models—it’s also about pushing the boundaries of what’s possible in engineering design. By offering a visual and interactive representation of products, engineers can experiment with new concepts, materials, and technologies in ways that were previously impossible. This fosters greater creativity and innovation in the design process.

Future Trends in 3D Product Visualization for Engineers

The future of 3D product visualization is exciting. Advancements in artificial intelligence, machine learning, and augmented reality (AR) are expected to make these tools even more powerful. AR, in particular, will allow engineers to visualize their designs in the real world, providing a more immersive experience. As these technologies continue to evolve, the possibilities for engineering product design will be limitless.

Conclusion

3D product visualization is transforming the way engineers approach design and prototyping. From streamlining the prototyping process to reducing errors and fostering innovation, the benefits of 3D rendering and prototyping are clear. As technology continues to advance, engineers will have even more powerful tools at their disposal to create groundbreaking products and designs. Embracing these technologies today will ensure success in tomorrow’s competitive engineering landscape. Embracing these technologies today will ensure success in tomorrow’s competitive engineering landscape, as highlighted by resources like NexxImage.

FAQs

What is 3D product visualization in engineering?

3D product visualization in engineering refers to the creation of realistic digital models of products to aid in design, prototyping, and testing, ensuring a clear understanding of the product before production.

How does 3D prototyping help engineers save time and money?

By enabling engineers to create and modify digital prototypes, 3D prototyping reduces the need for physical models, thus cutting down on both time and material costs.

What is the role of digital twin technology in 3D product design?

Digital twin technology allows engineers to create a virtual replica of a physical product, enabling real-time simulations and adjustments to improve design accuracy and performance.

How does 3D rendering improve product accuracy in engineering?

3D rendering allows engineers to visualize and test designs in great detail, reducing the likelihood of errors and ensuring the final product meets specifications.

What are the future trends in 3D visualization for engineers?

The future of 3D product visualization will likely involve the integration of AI, machine learning, and AR to enhance design processes, simulations, and real-world applications.