Equipment installation is one of the most expensive phases of industrial operations. According to Forbes, unplanned downtime costs manufacturers an estimated USD 50 billion annually, which is spent on the best 3D technologies in the industry, including advanced 3D modeling and animation services worldwide, with equipment installation errors being a key contributor.

For Australian suppliers operating in mining, agriculture, construction, food processing, and heavy industry, even minor installation mistakes can delay entire production lines.

This is where 3D installation animation becomes a powerful tool.

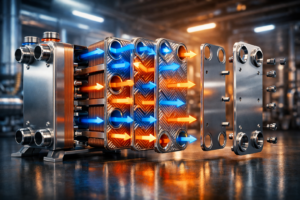

3D animation enhances industrial equipment by providing step-by-step visualisation of machinery assembly, positioning, alignment and safety procedures. It gives teams a clear view of how equipment should be installed long before it arrives on site, reducing guesswork, preventing errors, and ensuring smoother installation workflows.

How 3D Animation Reduces Installation Downtime?

Using Animation and 3D Rendering for Clear Installation Instructions

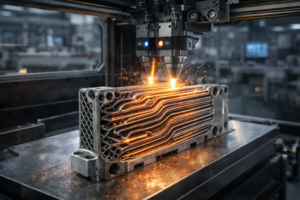

3D installation animation uses a combination of 3D modelling, 3D rendering, CAD files, animation services and technical 3D visualisation to illustrate complex installation steps. This helps technicians understand complex systems through interactive 3D visualizations.

-

Where each component is positioned

-

Which tools are needed for effective CAD modelling and animation services?

-

What sequence to follow

-

Safety zones and hazard points

-

How to avoid common installation errors

This improves accuracy and dramatically reduces trial and error on-site. Visual assembly instructions improve task performance and reduce human errors by up to 80 percent.

3D CAD and Model-Based Visualisation for Installation

Using CAD and 3D Models in Installation Planning

Most Australian suppliers already work with CAD drawings, but they rarely visualise them in an animated format. When CAD is converted into a 3D model and then animated, installation teams can see:

-

Life-like images and animated videos

-

Exploded views of equipment

-

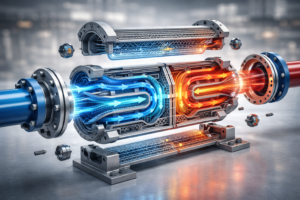

Cutaway views showing internal mechanical design

-

Correct bolt patterns and alignment points can be visualized effectively using 3D modelling since the early 2000s.

-

Detailed 3D overlays for precise measurements enhance the animation of hydraulic hose crimping.

This transforms CAD from static 2D drawings into interactive 3D visual tools.

Interactive 3D and Immersive Visualisation for Complex Equipment

How Interactive 3D Helps Teams Learn Faster?

Interactive 3D tools allow teams to rotate equipment, zoom into mechanical design, view hidden components, and replay installation sequences, enhancing the overall 3D visualization experience with high-quality animations. These are especially useful for:

-

Mining equipment and 3D visualization technologies are essential for modern operations.

-

Hydraulics benefit significantly from 3D animation of hydraulic hose crimping, making complex systems easier to understand.

-

Conveyors

-

Electrical systems

-

Industrial automation

-

HVAC and power distribution systems

When teams can practice installation virtually, they reduce mistakes on-site.

3D Animation in Australia: Use Cases Across Industries

How Companies in Australia Use 3D Animation for Installation?

Across Australia, many industries rely on 3D animation to improve installation efficiency:

-

Mining and resources can benefit from 3D animation showcases to visualize processes effectively.

-

Manufacturing

-

Transport and logistics

-

Food and beverage

-

Agriculture

-

Construction and civil engineering

Animation is used to show assembly, commissioning, testing, and safety procedures, with a focus on 3D animation enhancing clarity. These animated videos help reduce delays and support both training and marketing, showcasing the capabilities of an animation company.

Why 3D Installation Animation Outperforms Traditional Manuals?

| Feature includes the use of CAD modelling and animation services for enhanced visual communication. | Traditional Manuals | 3D Installation Animation |

|---|---|---|

| Visual clarity | Low-quality visuals can hinder the effectiveness of 3D visualization. | High-quality 3D |

| Accuracy | Depends on drawings | Based on CAD and 3D models |

| Training value | Limited | Interactive 3D and immersive learning using Matterport 3D virtual tours enhances the educational experience. |

| 3D animation enhances error reduction through the use of 3D visualization techniques, showcasing hydraulic hose benches. | Moderate improvements in efficiency can be achieved with the animation of hydraulic hose bench processes. | Significant error reduction |

| Installation speed | Slower | Faster installations |

| Engagement | Low | Visually engaging animation video |

3D Animation Services That Support Installation Workflows

What an Animation Studio Provides?

A specialized animation company can create 3D content tailored to industry needs. A 3D animation studio can create intricate designs for hose crimping and production benches.

-

3D CAD modelling and animation

-

3D rendering

-

3D animation and motion graphics

-

Explainer video production

-

Industrial equipment animation

-

2D and 3D animation

-

High-quality 3D installation sequences

-

Interactive 3D learning tools, including Matterport 3D virtual tours of 19 different equipment types, revolutionize training.

These services help suppliers communicate product design and installation requirements clearly across Australia through CAD modelling and animation services.

Bringing Your Equipment to Life Before It Hits the Floor

Modern installation challenges demand clearer communication, faster training and fewer on-site delays. This is where 3D installation animation becomes a genuine game-changer for Australian equipment suppliers. By turning CAD data and complex engineering information into easy-to-understand visual sequences, teams can walk through every step of the installation long before the equipment arrives. This reduces uncertainty, prevents costly mistakes and keeps projects running on schedule.

High-quality 3D visualisation also supports safer operations by highlighting hazards, alignment requirements and assembly procedures in a format that technicians can absorb quickly. Whether you are introducing new machinery, training a dispersed workforce or improving customer support, 3D animation provides a level of clarity that written manuals or 2D drawings can never match.

If you want to streamline installation and communicate your equipment with absolute precision, explore what dedicated industrial and engineering 3D animation can do for your team.

FAQs: Common Questions About 3D Installation Animation

What are the benefits of 3D product animation for installation?

3D product animation gives technicians a clear, visual understanding of every installation step, making complex instructions easier to follow. It reduces guesswork, prevents common assembly mistakes and improves on-site accuracy. With better visualisation, teams complete installations faster and with fewer errors, which helps reduce downtime.

How long does it take to create a 3D animated video?

The timeline depends on the complexity of the equipment and the level of detail required. Simple installation animations typically take two to three weeks to develop. Larger machinery, multi-step systems or animations built directly from CAD models can require four to eight weeks. The process includes modelling, rendering, animation and review cycles.

Can 3D animation illustrate heavy equipment operation?

Yes, 3D animation can accurately demonstrate how heavy equipment operates, including internal mechanisms and moving components. It provides clear mechanical visualisation for safety training, installation guidance and operational understanding. This helps teams grasp proper usage without needing physical access to the equipment.

What types of 3D product animations do equipment suppliers need?

Suppliers commonly use exploded views, cutaway animations and step-by-step installation sequences to explain complex machinery. Interactive 3D models can also help teams rotate equipment and view hidden parts. These formats improve clarity during installation and support both training and customer education.

Why is technical process animation effective for training?

Technical animations break down complex mechanical processes into easy-to-understand visual steps. They improve comprehension by showing real movement, correct sequences and safety requirements in a clear format. Because people retain visual information longer, animated training reduces errors and speeds up learning.